Welcome to Ronald India | No.1 Top Paper Bag Making Machine Manufacturer

Request Your Free Quote Now

Upgrade Your Packaging with Ronald’s Best Paper Bag Making Machines. Reliable, high-quality Kraft paper bag machines tailored for every business need.

V-Bottom Machine

It helps in making good quality paper bags with V bottom with or without gazette that are mainly used in medical and shops.

Square Bottom Machine

Option with inline printing and automatic square bottom machine with handle & Quick changeover of the Tube Formation Plates

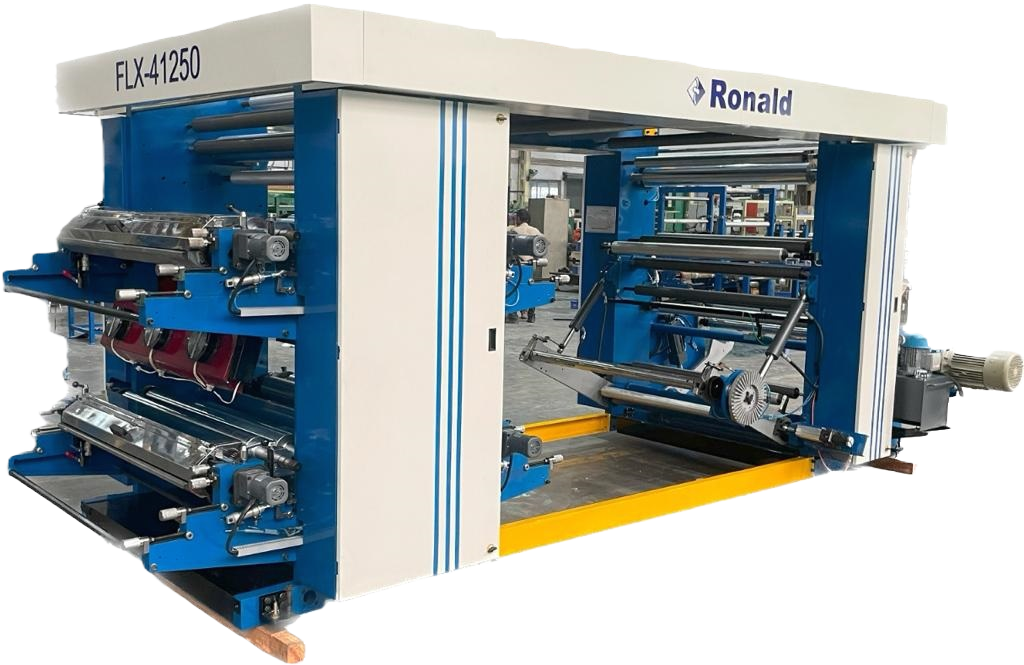

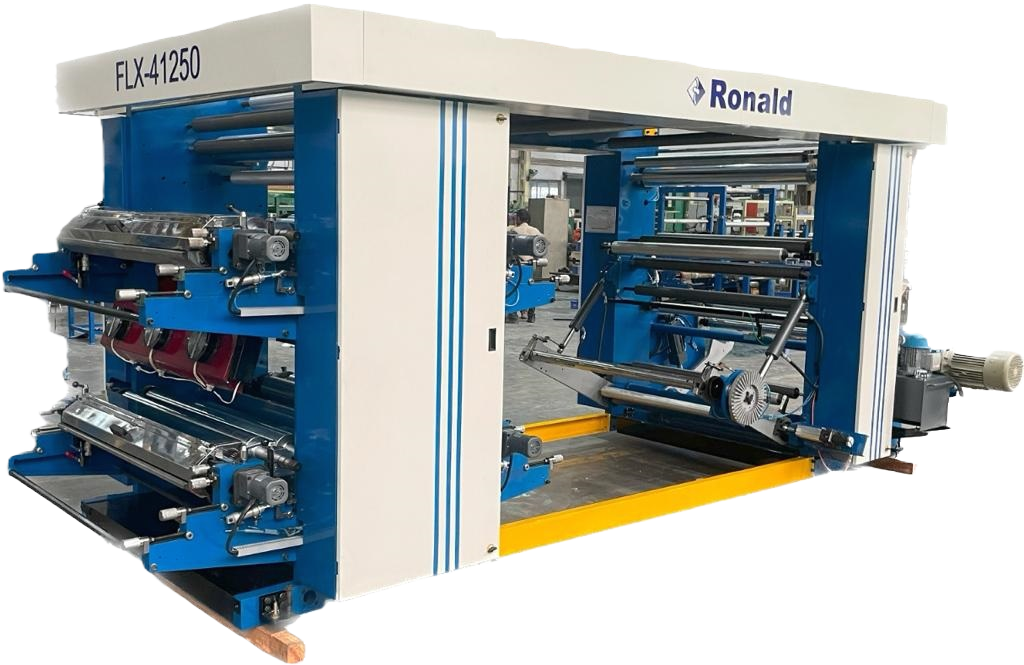

Flexographic Printing Machine

Stack type Flexo is a high speed Flexo printing machine It has ability to print on various substate such as Paper bag, Paper cups & many more

Always deliver more than expected.

About us

Welcome to Ronald Web Offset, a family-owned company with over 40 years of expertise in manufacturing high-quality machinery. Since 1983, we have been dedicated to providing reliable and efficient solutions, including our top-tier paper bag making machines. As the demand for eco-friendly packaging rises, our machines empower businesses to embrace sustainable practices without compromising on quality. Trust Ronald India for exceptional service and innovative packaging solutions.

established year

Installation

Why Choose Us

Square Bottom Machine

Square Bottom Paper Bag Making Machine with Inline Printing

The Square Bottom Paper Bag Making Machine with Inline Printing is designed to revolutionize your packaging process. This advanced machine produces high-quality square bottom paper bags with the option for inline printing, making it ideal for businesses looking to enhance their branding while maintaining efficient production. It caters to various industries, ensuring your packaging meets both functional and aesthetic needs

- Quick Changeover of Tube Formation Plates: Facilitates rapid adjustments for different bag sizes, minimizing production downtime.

- Easy Touch Operation: User-friendly interface allows for straightforward machine operation, making it accessible for all operators.

- Compact and Easy to Handle: Designed with a space-efficient layout, perfect for diverse production environments.

- Automatic Counting System: Keeps track of the number of bags produced for effective inventory management.

- Dynamically Balanced Rollers and Cylinder: Reduces vibration, ensuring smooth and stable operation.

- On-the-Run Adjustment of Bag Size: Easily modify bag dimensions during operation without halting production.

| Specification | RSB 230 | RSB 360 | RSB 450 | RSB 450 B |

|---|---|---|---|---|

| Bottom Size (H) | 50-130 mm | 70-205 mm | 70-205 mm | 100-250 mm |

| Bag Width (W) | 80-230 mm | 135-360 mm | 230-450 mm | 230-450 mm |

| Bag Tube Length (C) | 190-430 mm | 270-530 mm | 270-530 mm | 350-740 mm |

| Max Speed | 220 pcs/min | 200 pcs/min | 170 pcs/min | 125 pcs/min |

| Paper Thickness | 45-120 GSM | 50-160 GSM | 60-160 GSM | 80-160 GSM |

| Max Roll Diameter | 1200 mm | 1200 mm | 1200 mm | 1200 mm |

| Paper Roll Width | 280-750 mm | 435-1150 mm | 650-1350 mm | 700-1450 mm |

| Total Power | 8 kw | 10 kw | 10 kw | 12 kw |

| Machine Weight | 6500 kg | 8500 kg | 9500 kg | 11000 kg |

| Machine Dimension (LxWxH) | 8500 x 1800 x 1950 mm | 10000 x 2000 x 1900 mm | 10000 x 2200 x 1900 mm | 10700 x 2400 x 2000 mm |

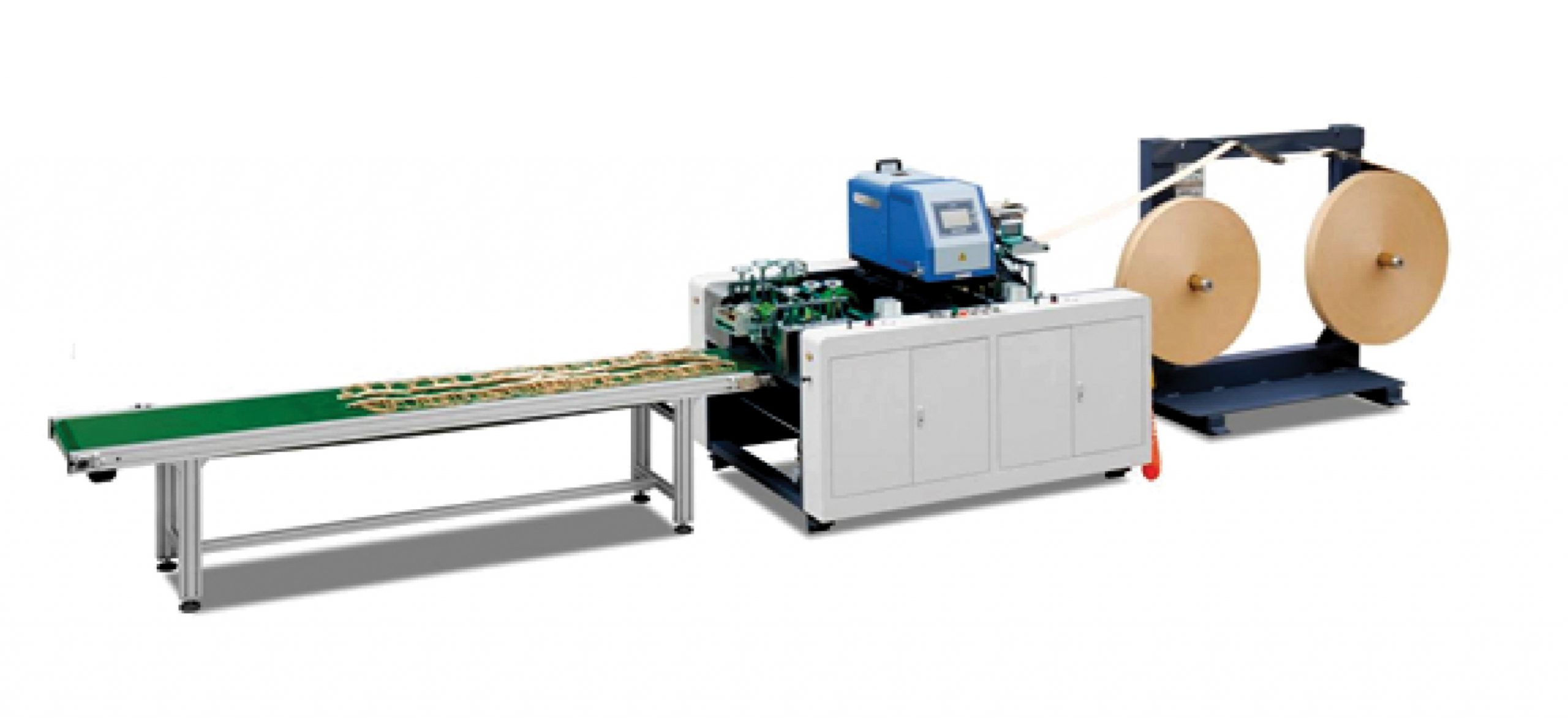

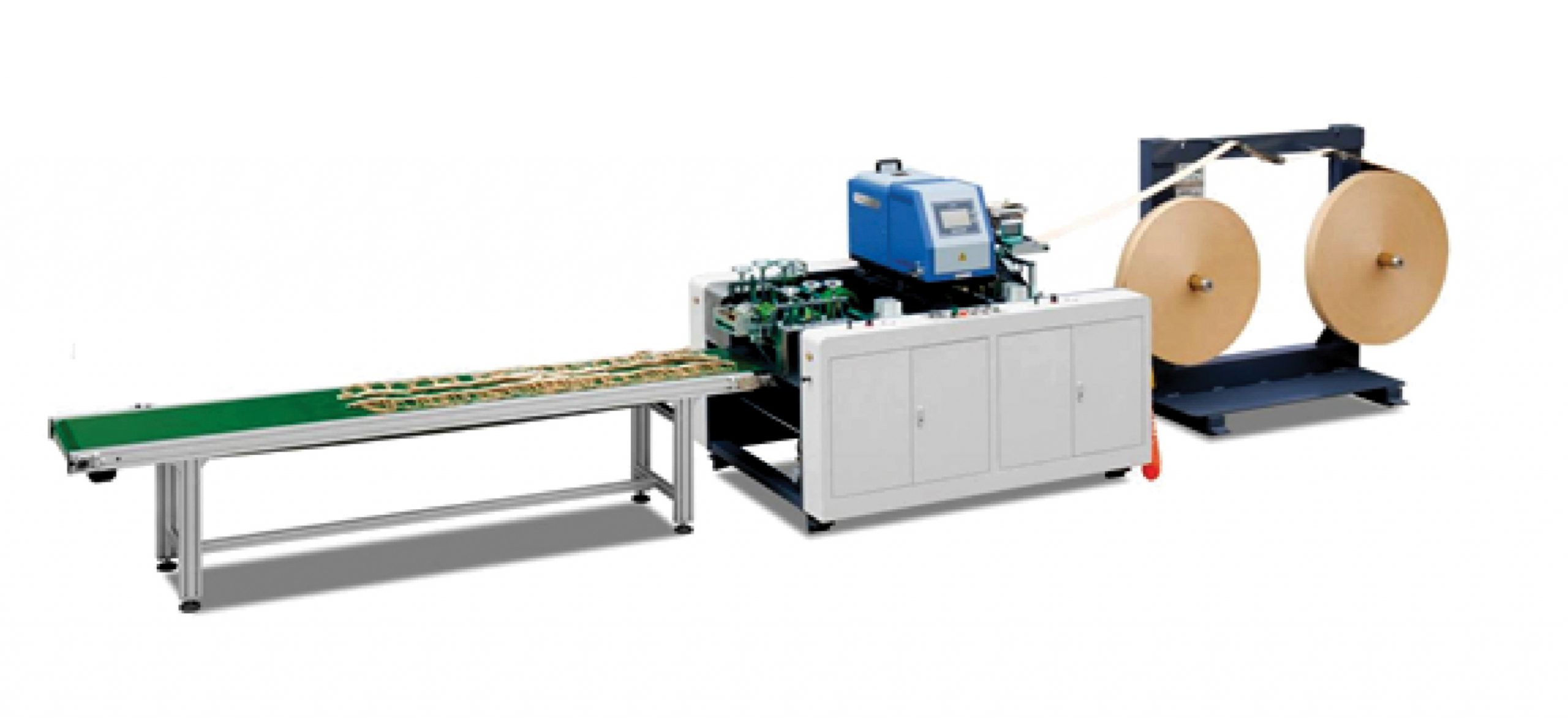

Automatic Square Bottom Machine with Handle

The Automatic Square Bottom Machine with Handle is engineered for high-volume production of square bottom paper bags, providing an efficient solution for your packaging needs. This machine combines automation with ease of use, allowing for consistent quality and performance in the production of bags suitable for various applications, including retail and food packaging.

- Anilox Cylinder with Doctor Blade Assembly: Ensures sharp, high-quality printing for striking designs on your bags.

- HMI Screen for Machine Operation: Intuitive interface simplifies monitoring and controlling the machine functions.

- Automatic Side Gluing System: Streamlines the gluing process for uniform adhesion and improved bag integrity.

- Web Aligner: Guarantees precise positioning of the material, reducing waste and enhancing accuracy.

- Pneumatic Brake System: Maintains consistent tension during operation, ensuring uniform bag production.

- Automatic Counting System: Efficiently tracks the production output, facilitating better inventory management.

- Quick Changeover of Tube Formation Plates: Allows for fast adjustments to different bag sizes without significant downtime.

- Compact and Easy to Handle: Designed for versatility, ensuring ease of operation in various production settings.

| Specification | RSB-360-ACE | RSB-450-ACE |

|---|---|---|

| Cutting Length | 270-530 mm | 270-530 mm |

| Cutting Length (with Handle) | 270-430 mm | 270-430 mm |

| Bag Width | 150-360 mm | 220-450 mm |

| Bag Width (with Handle) | 220-360 mm | 290-450 mm |

| Bag Length | 225-370 mm | 225-470 mm |

| Bag Length (with Handle) | 225-370 mm | 225-370 mm |

| Bottom Width | 70-205 mm | 80-205 mm |

| Paper Thickness | 50-120 g/m² | 80-120 g/m² |

| Paper Roll Width | 500-1150 mm | 630-1370 mm |

| Roll Paper Diameter | 1200 mm | 1200 mm |

| Paper Core | 76 mm | 76 mm |

| Handle Height | 100 mm | 100 mm |

| Patch Length | 190 mm | 190 mm |

| Patch Width | 40-50 mm | 40-50 mm |

| Handle Distance | 75 mm | 95 mm |

| Rope Diameter | 3-5 mm | 3-5 mm |

| Patch Paper Roll Width | 80-100 mm | 80-100 mm |

| Patch Paper Roll Diameter | 1200 mm | 1200 mm |

| Patch Paper Thickness | 100-135 g/m² | 100-135 g/m² |

| Max. Machine Speed (Bags without Handles) | *200 bags/min | *200 bags/min |

| Max. Machine Speed (Bags with Handles) | *120 bags/min | *120 bags/min |

| Machine Weight | 1200 kg | 13500 kg |

| Machine Size | 14000 x 6000 x 2400 mm | 14000 x 6000 x 2400 mm |

V-Bottom Paper Bag Making Machine (RVB Series)

Introducing our RVB Series V- Bottom paper bag making machines, a true game changer in the paper bag manufacturing industry. Engineered for efficiency and quality, these machines produce high-quality V-bottom paper bags, with or without gussets, making them ideal for grocery stores, medical facilities, and confectionery shops.

Pneumatic Reel Lifting: Effortlessly lift heavy rolls from the ground, enhancing operational efficiency and reducing manual labor.

Pneumatic Brake with Auto Tension Control: Ensures consistent tension during operation, resulting in uniform bag production and reducing material waste.

Dancing Roller Mechanism: Effectively controls tension, providing smooth and reliable operation throughout the manufacturing process.

Quick Changeover of Tube Formation Plates: Facilitates swift adjustments between different bag sizes, maximizing productivity and minimizing downtime.

On-the-Run Size Adjustment: Easily modify bag dimensions during production, allowing for versatility and flexibility in your product offerings.

Two-Roller Glue System: Delivers superior pasting strength, ensuring bags are securely sealed and ready for use.

High-Carbon and High-Chromium Cutting Knives: Durable and efficient cutting knives provide precise and clean cuts, enhancing the overall quality of the bags.

Inline Printing Option: Our RVB Series includes an inline printing unit, allowing for seamless integration of printing into the production process. This feature not only saves time but also reduces labor costs. Customers can choose between two and four color printing options.

Servo Drive Unit with Print Mark Sensor: Ensures perfect cuts on printed materials, enhancing the overall precision and aesthetics of the finished bags.

Special Sizes Available on Request: We can customize the machine to meet your specific production needs, ensuring you get the perfect solution for your business.

| Specifications | RVB 1018 | RVB 1418 | RVB 1824 |

|---|---|---|---|

| Bag Length | 140-455 mm | 140-455 mm | 180-605 mm |

| Bag Width | 80-270 mm | 80-350 mm | 100-450 mm |

| Gusset | 0-100 mm | 0-125 mm | 0-175 mm |

| Standard Flap | 12-20 mm | 12-20 mm | 12-20 mm |

| Max Speed | 500 Bags/Min | 500 Bags/Min | 400 Bags/Min |

| Paper Thickness | 30-90 GSM | 30-90 GSM | 30-120 GSM |

| Paper Roll Width | 200-760 mm | 200-1000 mm | 250-1290 mm |

| Max Roll Diameter | 1000 mm | 1000 mm | 1000 mm |

| Total Power | 3.7 kW | 3.7 kW | 5.7 kW |

| Glue Motor | 90 W | 90 W | 90 W |

| Overall Dimensions | 5000 x 1600 x 1700 mm | 5500 x 1900 x 1700 mm | 6500 x 2400 x 1800 mm |

| Weight of Machine | 2500 kg | 3000 kg | 4500 kg |

The RVB Series V-Bottom Paper Bag Making Machine stands out for its reliability and innovative features. By investing in this technology, you not only enhance your production capabilities but also ensure that your products meet the highest quality standards.

Experience the difference that advanced engineering and design can make in your paper bag production. For more information or to discuss your specific needs, contact us today!

Ready to elevate your packaging solutions?

Discover how our high-quality paper bag making machines can transform your business. Whether you’re looking for a quote or want to schedule a demo, our expert team is here to help you every step of the way!

Don’t wait—let’s create a sustainable future together!

Contact Us Today for a Personalized Consultation!

Phone:

+91-99103 06205

+91-99103 06210

Email:

info@ronaldweboffset.com

Clients Love

Testimonial

"We invested in Ronald India’s V-Bottom Paper Bag Making Machine, and it has transformed our production line. The machine is user-friendly, efficient, and produces high-quality bags that our customers love. The support from Ronald's team has been exceptional, making the transition smooth and hassle-free."

"Choosing Ronald India was a game changer for our business. Their Square Bottom Paper Bag Making Machine is incredibly reliable and has significantly increased our output. The inline printing option has allowed us to enhance our branding, making our bags stand out. Highly recommend!"

"As a small business owner, I needed a machine that was both affordable and efficient. The Kraft Paper Bag Machine from Ronald India exceeded my expectations. It’s compact, easy to operate, and produces bags that meet our eco-friendly standards. I couldn’t be happier with my investment!"

Product Range

• Other Related Products

FLEXO GRAPHIC PRINTING MACHINE

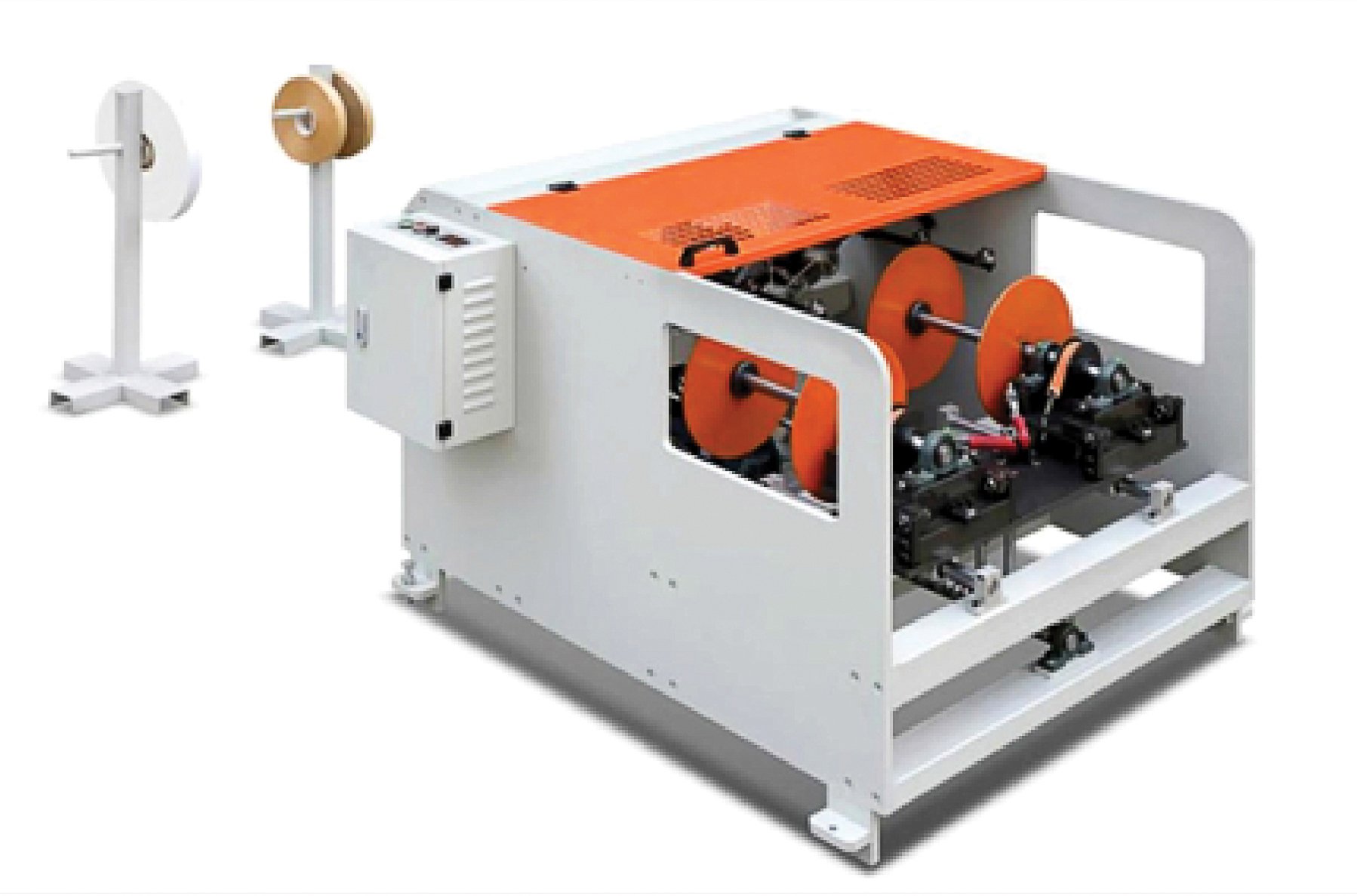

TWISTED PAPER ROPE

TWISTED PAPER ROPE HANDLE MAKING MACHINE

HANDLE MAKING MACHINE

FAQs for Ronald India - Paper Bag Making Machines

1. What is a Paper Bag Making Machine?

2. What types of paper bags can you produce?

3. Why should I choose a Kraft Paper Bag Machine?

4. In which countries does Ronald India operate?

5. How can I reach customer support for assistance?

6. What benefits does an Automatic Paper Bag Making Machine offer?

7. Can the machines be customized for different bag sizes?

8. What printing options are available for the bags?

9. Are your machines suitable for small businesses?

10. How do Ronald India's Paper Bag Making Machines operate?

Served in 30+ countries

Featured in 100+ Recognitions